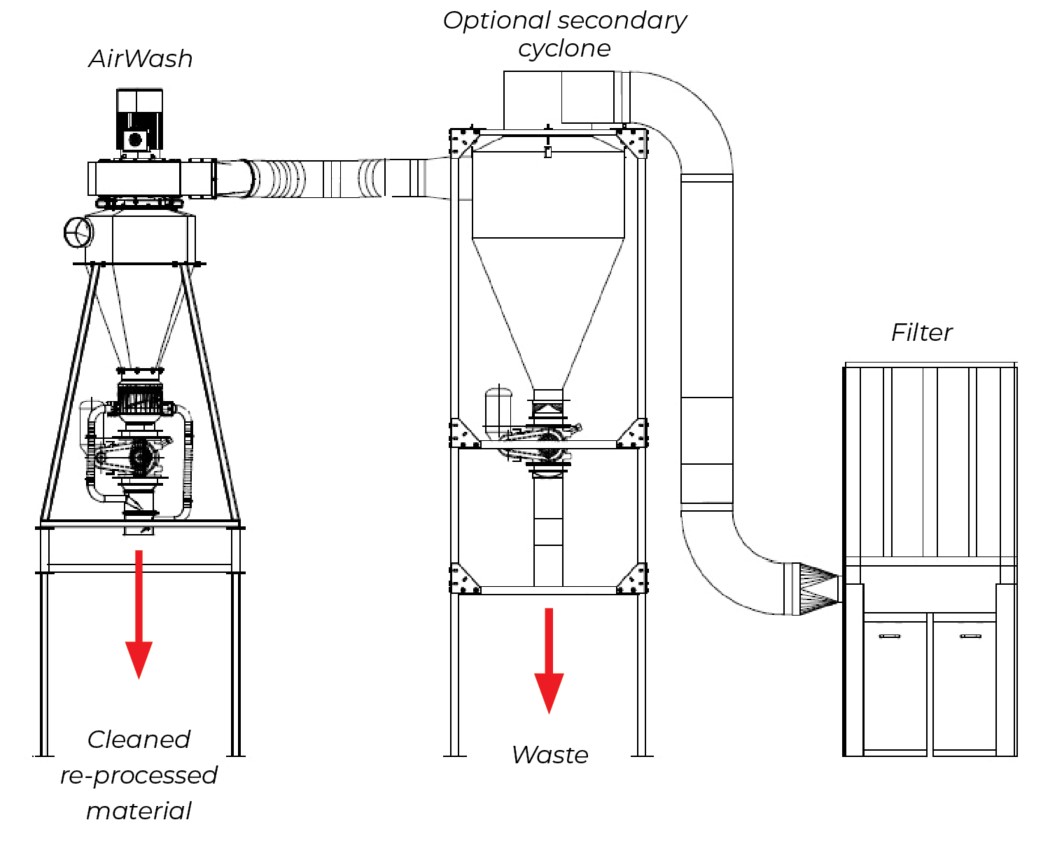

How the AirWash System Works for Material Dedusting and Recycling

The AirWash system offers an innovative approach to material separation and cleaning, critical for facilities seeking to maximize the quality of recycled plastic. By removing unwanted fines and dust, the AirWash enhances material cleanliness and boosts the value of reprocessed plastics.

As resin prices rise and recycling gains importance, the AirWash system provides an efficient and economical solution for handling plastic regrind. This aspiration-based dedusting system uses a two-step cleaning process to achieve precision separation:

- Cyclone Separation: Material enters the separation cyclone, where air vortexes clean the plastic regrind, removing fines and impurities.

- Cascade Cleaning: In the cascade section, material falls by gravity through adjustable vacuum slots, ensuring thorough cleaning.

Once processed, the clean regrind can be reintroduced directly into the production line, making the AirWash system ideal for in-house recycling and consistent, high-quality material output.

Compatible Materials for the AirWash Dedusting System

The AirWash system is versatile and supports a wide range of plastic materials commonly used in industrial applications. Examples include:

- PP

- PET

- PE

- HDPE

- Nylon

- Fibers

- ABS

- Carpet

- Rubber

- Acrylics

- Polystyrene

- and more

Key Benefits of the AirWash System

- Improved Production Cleanliness: Removes dust and fines, reducing facility cleanup requirements.

- Increased Material Throughput: Efficiently handles large volumes of plastic regrind.

- Enhanced Reuse of Scrap: Maximizes recycling potential and reduces raw material costs.

- Higher Quality Regrind: Produces cleaner, more consistent regrind for seamless reintegration into production.

- Optimized Production Efficiency: Supports continuous operation, minimizing downtime.

Unique Features of the AirWash System

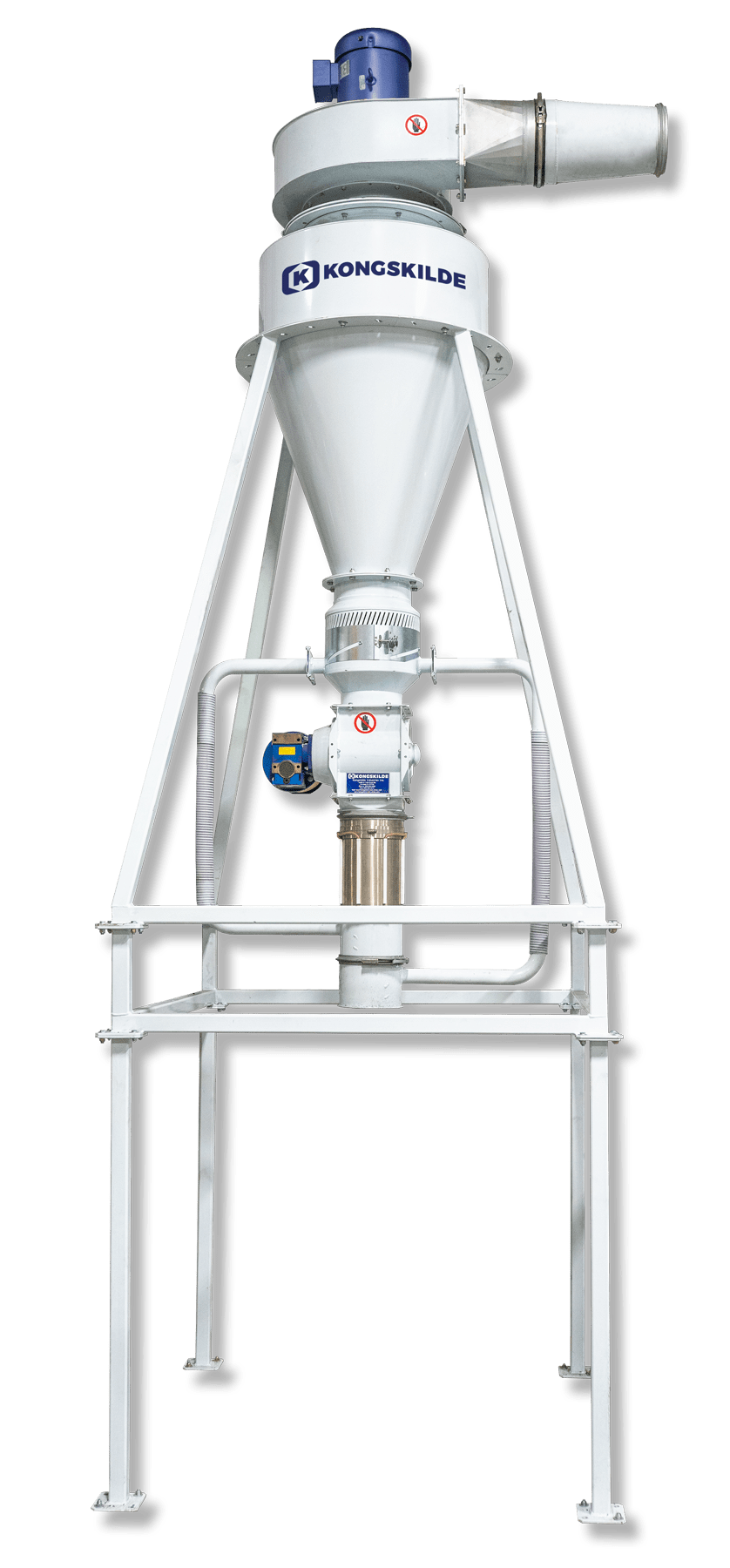

The AirWash system’s modular design and advanced features make it easy to integrate into existing production facilities and adjust to specific operational needs:

- Modular Components: Flexible installation options for easy integration.

- Swivel Hinge for Blower: Enables quick inspection, cleaning, and maintenance.

- Antistatic Eliminator: Optional antistatic feature near the material outlet for handling static-prone materials.

- Filter Bag Manifold: Available with collection drums for batch processing or for continuous operation.

- Optional Dust Cyclone with Airlock: Provides additional dust control when used with the filter bag manifold.